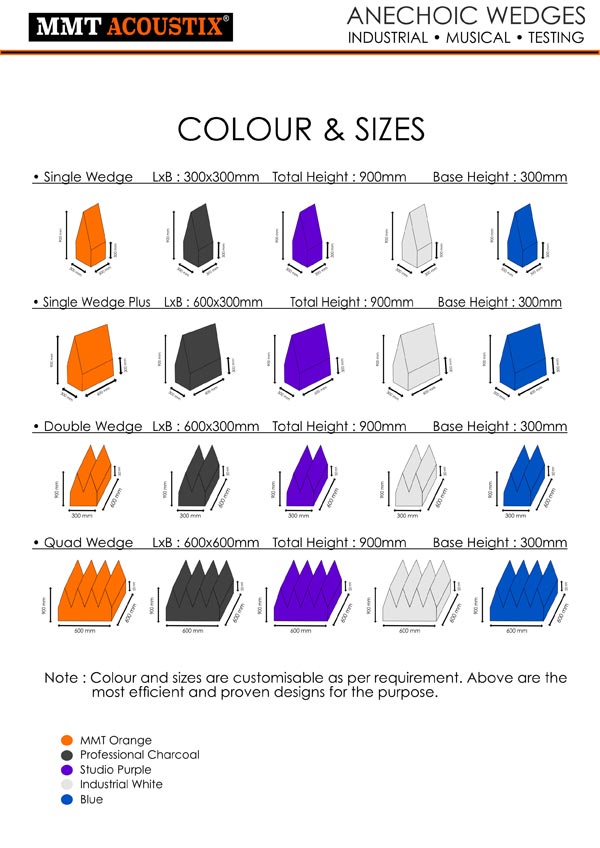

Anechoic Wedges

MMT Acoustix manufactures medium/high density acoustic polyurethane anechoic wedges

for maximum sound diffusion and absorption. The wedges are designed to diffuse and

absorb sound at the same time. The depth and thickness of the wedges are maximized

to achieve 20-30 DB sound levels. MMT Acoustix Anechoic Wedges are available in

various sizes and colours as per client's requirement.

Anechoic chambers are commonly used in acoustics to conduct experiments in nominally "free field" conditions, free-field meaning that there are no reflected signals. All sound energy will be traveling away from the source with almost none reflected back. Common anechoic chamber experiments include measuring the transfer function of a loudspeaker or the directivity of noise radiation from industrial machinery. In general, the interior of an anechoic chamber is very quiet, with typical noise levels in the 10–20 dBA range.

The basic principle behind making a room quiet to such high degrees is to ensure that there are almost no rebounding sound waves, meaning that all sounds are absorbed by the room itself. To achieve this, anechoic rooms are lined with Acoustic Foam Wedges that cover the entire ceiling, floor and walls. This creates an uneven surface of a wedge network protruding from different directions. When sound waves strike the acoustic foam wedges they are transferred to the body of a wedge, where the wave energy is effectively dissipated. Any residual sound (wave) reflects off the wedge at an angle and lands on another wedge under going the same process again. In this way, all of the energy of a sound wave is dissipated, so there’s no echo and the room becomes unbearably quiet.

Anechoic chambers are commonly used in acoustics to conduct experiments in nominally "free field" conditions, free-field meaning that there are no reflected signals. All sound energy will be traveling away from the source with almost none reflected back. Common anechoic chamber experiments include measuring the transfer function of a loudspeaker or the directivity of noise radiation from industrial machinery. In general, the interior of an anechoic chamber is very quiet, with typical noise levels in the 10–20 dBA range.

The basic principle behind making a room quiet to such high degrees is to ensure that there are almost no rebounding sound waves, meaning that all sounds are absorbed by the room itself. To achieve this, anechoic rooms are lined with Acoustic Foam Wedges that cover the entire ceiling, floor and walls. This creates an uneven surface of a wedge network protruding from different directions. When sound waves strike the acoustic foam wedges they are transferred to the body of a wedge, where the wave energy is effectively dissipated. Any residual sound (wave) reflects off the wedge at an angle and lands on another wedge under going the same process again. In this way, all of the energy of a sound wave is dissipated, so there’s no echo and the room becomes unbearably quiet.

Product Detail

Application Industry:

Anechoic chambers block audible noises by forcing the acoustic waves to

bounce upon impacting the pyramidal foam, causing the waves to lose energy

with each bounce. They also block electromagnetic waves, which include radio

waves, with the assistance of an exterior screened room or ferrite walls